|

|

||||

|

|

||||

|

|

||||

|

|

Things We Made, Things We Did Two young men had some spare time on their hands. One man asked

the other man: "What are you going to do in your spare time?" "I think I will make myself comfortable in my favourite chair

and I will read a good book," answered the other man. "What are you going to do in your spare time?" asks the

first man. "I will go into my shed and I will make a nail," he answered. The first man read his book and the second man made a nail. Now

they asked one another again. "What will you do now?" asked one of them. "I will read another book," he answered. The other man said that he will make another nail. You can't stop people from doing what they want to do, or what they

want to make. If you want proof of that just look at how many books

there are in the libraries and look at how many nails and other things

there are in the Bunnings warehouses. The man who made the nail helped

start the industrial revolution and look how far he has advanced mankind.

The man who read his book helped the civilisation of mankind and now

look how civilised, healthy and comfortable we are. I was a boy who

wanted to make nails, figuratively speaking. And now that I am an

old man I still enjoy making nails, figuratively speaking. Richmond Technical school taught me how things work and provided

me with the facilities to make nails and other useful things. Listed

below are brief descriptions of some of the things students in technical

schools made. 1. In Woodwork they learned to sharpen chisels, plane blades and such. They learned how to maintain all the carpentry tools. With those tools they made a pencil case, a fruit bowl and a coffee table. 2. In the Sheet Metal workshop they learned how to solder sheets of metal together and they learned how to bronze-weld using oxy-acetylene welding equipment. They made oil cans and they joined sections of downpipes together. 3. In the machine shop they learned how to cut and shape metal and

how to make things out of metal. The machine shop was equipped with

lathes, shaping machines, drill stands, grinders and all sorts of

hand tools. A student could make a whole car if he wanted to. My brother

nearly made a car; this comes later. The machine shop was my favourite workshop, students called it "turning

and fitting". Because that is precisely what they did there.

They turned metal on the lathe and they made things that fitted together

to make tools such as a soft metal hammer (I still have it at home),

a G-clamp used to clamp parts together (I lost it), a bottle car jack

(I wish I kept it). The bottle car jack deserves more page space here because it was

a proper engineering project. The body of the car jack was made out

of cast iron and it was made by pouring molten iron into a casting

mould at a foundry in Richmond. We went to the foundry and watched

the casting of the bottle car jack. Back in the school's turning and

fitting workshop, we cut a "square-female" thread into the

body of the car jack. And then we turned a round shaft and cut a matching

"square-male" thread onto it to complete the car jack that

could lift a full-size car. In addition to the mandatory items made

at school, my brother and I made our personal toys with the blessing

of the teachers at the senior apprentices' school. We were in a tech-nerd's

paradise. Before the age of 18 my brother Steve purchased a non-running Austin

Healey Sprite Mark 1. He paid the wreckers $240.00 for it and he proceeded

to repair it and make it roadworthy. We dismantled its engine and

brought the crankshaft to the senior tech for it to be ground by the

apprentices. The crankshaft has seven journals, and seven apprentices

ground one journal each and each journal was ground to a different

diameter. This caused additional complexities for us in reconditioning

the engine, but we eventually completed the engine. We managed to

put the car together and we spray-painted it as well. This was proof

that one could make a car at Richmond Tech. More specific details about completing the car could increase the

risk of losing my readers at this point. So I will move forward to

a more people-related incident involving the rigorous roadworthy checking

and registration of Steve's Sprite at the VicRoads centre, which was

located in Lygon Street, Carlton. A car without previous registration records, like the Sprite that

Steve bought from the wreckers without any official papers, had to

go through a thorough inspection over a dugout pit in the floor of

a workshop at VicRoads in Lygon Street. The date for the full inspection of the car was prearranged, the

Austin Healey Sprite was ready to go. I drove the car as Steve didn't

have his driver's licence yet. On the way to the inspection pit, I

noticed that the car wasn't running freely, it was reluctant to go.

The brakes started to lock, that is the brakes were "on"

even when I wasn't pressing the brake pedal. The roadworthy inspector

motioned me to drive the reluctant Sprite over the inspection pit.

I had to use almost all of the power that the little car could muster

to bring the car over the pit. While the car was stationary, the brakes

had a bit of time to cool down while the inspector was giving it a

health check. "Off you go," he calls out after the health check. But the little Sprite wasn't free from its jammed brakes and therefore

not ready to go without the extra revving of the engine. I managed

to drive the Sprite away from the inspection pit and I parked it as

soon as I could. The roadworthy inspector didn't notice that the car

had faulty brakes and unbelievably he gave us a roadworthy certificate

for a car with faulty brakes. This was after a thorough inspection

over the VicRoads roadworthy inspection pit. I couldn't believe it. It wasn't only full-size cars that we restored and worked on. Carmelo

and I made model aeroplanes powered by small two-stroke glow plug

engines. The glow plug engines didn't need a spark plug or a distributor

to power the engine. They required an external battery to heat the

platinum wire in the glow plug. The hot wire ignites the volatile

fuel mixture that was called ether, a mixture of methanol, nitromethane

and oil. After a few flicks of the engine's propeller with my finger

the engine would start spinning. Starting the little engine was done

in a similar way to how the early propeller driven air force planes

were started. We flew the planes by a hand-held control device made of two fishing

lines. We flew the planes in large overhead circular orbits. By holding

the lines steady we kept the planes flying in a circle. By moving

the control handle sideways and thus controlling the ailerons of the

tiny planes, we could make the planes go up or down. It took great

skill to make the aeroplanes skim the ground and then make them climb

up again. We flew our planes on the school's oval after school hours. The

aeroplanes were amazing. We made them out of balsa wood according

to our designs. We shaped the balsa wood into the form of an aeroplane,

we sanded them smooth and brushed them with a substance called "dope"

to harden the surface of the planes so we could rub them to a smoother

finish for a better aerodynamic performance. We taught ourselves about the profile of the wings, which gives

the aeroplane its lift, we learned about the attack angle which also

creates lift, and we learned about the "stall" angle of

aeroplanes. The stall angle is critical, it must not be exceeded.

Because if it is exceeded, it causes the plane to stall and to fall

out of the sky. We learned about the aerodynamics of planes and cars with the help

of one of our maths teachers, who was a car enthusiast himself. He

introduced us to the formula for the coefficient of drag, which indicates

how efficiently a car or a plane can move through the air. I remember

him emphasising that if you want to double the top speed of a car

you need to increase the engine power by a factor of eight. Wow, this

was fascinating, how was speed related to engine power? I wanted to

know more about this relationship and I eventually found out when

I was studying engineering. They were amazing years for science and engineering students. The

arrival of Donald Campbell's stunning Bluebird at Lake Eyre in South

Australa in 1964 could not have been better timed. The stunning Bluebird,

a streamlined car, set a land speed record of 403 miles per hour (mph)

for cars. The car's jet engine had over 3,000 kW of power and the

coefficient of drag was 0.16; igniting further interest about our

math teacher's above-mentioned statements. The wheels and tyres of

the Bluebird were specially designed by Dunlop, the tyre manufacturer,

to withstand the enormous centrifugal forces. We were studying physics, maths and engineering at school and out

of school hours. And the whole world was engrossed in the space race

between America and Russia; television news in the evening always

included a space race segment. Those tiny glow-plug engines could spin up to 20,000 revolutions

per minute. What a great engine to connect directly to the rear wheel

of a model car and to see how fast it would go, I thought to myself.

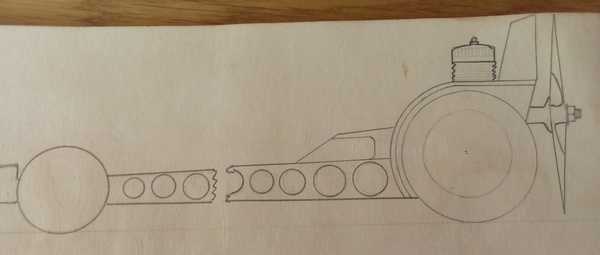

I made a 1/8 scale model of my dream car, the Jaguar E Type (my version

of the Bluebird). I made the wheel out of a round piece of aluminium

on the school's lathe and fitted on it a rubber tyre from one of my

aeroplanes and I fixed the wheel on to the E Type. The engine started with the first pull of the zip starter that was

also made with the school's lathe. But in no time at all the rubber

tyre expanded under the centrifugal force created by the spinning

wheel. The tyre flew off the wheel, damaging the right rear mudguard

of my E- Type Jaguar. Undeterred I wanted to use that glow plug engine on a propeller

driven car. So I made a rudimentary chassis and I attached four small

wheels on it. I secured the propeller fitted engine at the back of

the rudimentary four wheeled car. I started the engine and let the

car go, hoping to see the chassis-with-wheels set a new land speed

record for model cars. Disappointment was immediate as I watched the chassis-with-wheels

roll and eventually destroy itself. Confirming Newton's third law

of motion which states "To every action there is an equal and

opposite reaction". What a wonderful practical demonstration

of Newton's third law. The propeller wanted to go one way and the

engine together with the chassis went in the opposite direction. Had

the chassis been heavy enough, my propeller-driven car would have

worked and it would have moved forward and it would have accelerated

according to Newton's second law of motion. The second law of motion

states: The rate of change of momentum of a body is proportional to

the force causing that change in the momentum. From this relationship

one can derive the equation F = ma (F stands for force, m stands for

mass and a stands for acceleration). This equation is music to the

ears of a car enthusiast because it relates the force of the car's

engine to the acceleration of a car, and car enthusiasts love acceleration. My brother and I continued making model cars, including a basic

model racing car track that was set around the garden bed in our backyard.

We also entered an international model car competition, which nearly

landed me with a car designing job with General Motors Holden. Steve took a different direction and he made a small sailboat for

himself that he enjoyed using. I also made something different, not

involving cars as usual.

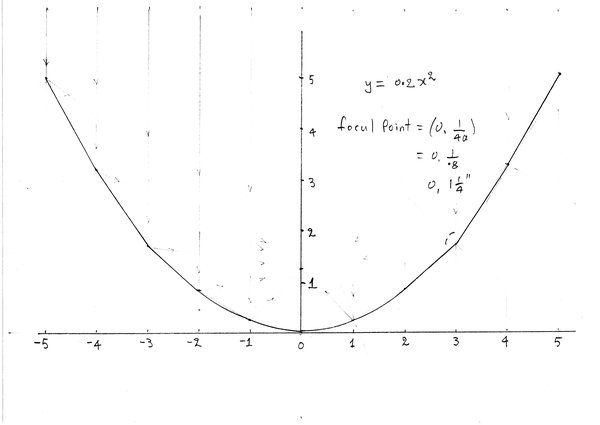

The same maths teacher who talked about the coefficient of drag

introduced us to quadratic equations and parabolic graphs during maths

classes. The parabolic graph, together with its focal point, struck

a chord with me when the maths teacher said that parallel rays of

light entering a parabolic mirror will reflect back and focus at the

focal point within the mirror. At that moment I had a brilliant thought and I wasted no time making

a parabolic dish that would demonstrate that concept. I went to the

apprentices' school and asked the teacher if his students could panel

beat for me a parabolically shaped dish out of aluminium about 200mm

in diameter. The teacher was happy to oblige as he was always looking

for interesting objects for his students to make. I did notice that they had knights' armour that they made displayed

on the walls of their workshop. This showed me that they can panel

beat anything. I polished the inside of the aluminium parabolic dish

that the apprentices made for me and I made it shine like a mirror.

The next step for me was to make a Stirling hot air engine during

the turning and fitting classes. I enjoyed turning the relatively

large brass flywheel and making the connecting rod, piston and the

finned cylinder (you must look up the Stirling engine online). I mounted

the engine in the parabolic dish with its cylinder head at the focal

point where the sun's rays were focused and thus heated the air in

the engine's cylinder. Well, to my amazement the Stirling hot air

engine worked. A very old engine design powered by solar energy -

a new age energy form, this was amazing. There will be more descriptions about solar powered cars in the

next chapter, but now let's move on to another interesting contraption

that I made at home and then we will check if those meat pies in the

oven are ready. If you think that the school's curriculum centred around physics

and maths relating to cars you would be wrong. Physics and cars are

what I concentrated on, because that is what I liked. The school covered

all academic subjects, sports and activities with the exception of

debates, something that private schools were concentrating on, presumably

because they were training their students for a socially interactive

life. Our school was training students for a technological workforce,

and it succeeded, as indicated by the 80 per cent of the final year

students who went on and studied engineering. Richmond Tech succeeded

in preparing its students for a technological world because the teachers

had practical work experience in the real world and they liked what

they were teaching. After school there was a very popular science show on TV called

Why Is It So? which I tried to watch as often as I could. Professor

Julius Sumner Miller was an excellent presenter and demonstrator of

scientific concepts on his show and he was able to engage students

with his love for physics.

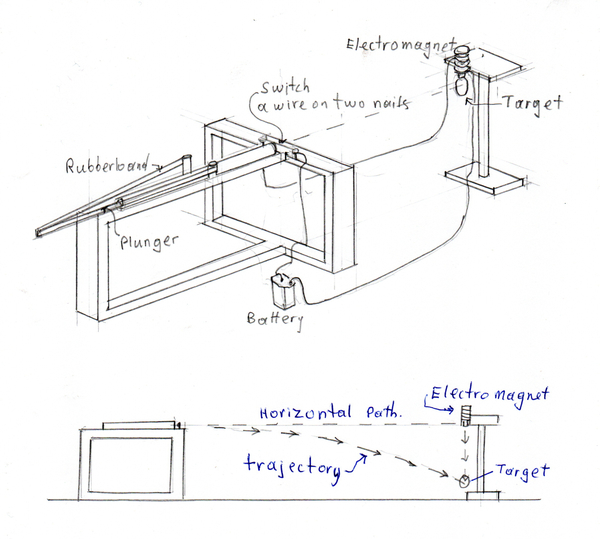

You too can make a similar device that proves that all objects fall

towards the centre of the earth at the same rate; then you can consider

yourself an experimental physicist and an engineer. This is what you need: 1. A long round tube, 25mm in diameter and about 1/2 metre long. 2. A small round object to be your projectile, e.g. a marble, a ball bearing, or a small dowel. 3. A strong rubber band so you can force the projectile along the tube at speed. 4. An electromagnet, made by winding lots of insulated electrical wire around an iron nail, a nine volt battery and a length of electrical wire that will act as a rudimentary switch to switch off the electromagnet. 5. A target, a small light object that the electromagnet can hold. You could use a piece of wood with a small nail in it so that the electromagnet can hold the piece of wood. 6. A bench or a frame to mount the channel horizontally and to attach the rubber band. 7. A stand to hold the electromagnet at the same height as the channel,

about 1 metre away from it. Method of operation: set up the equipment as shown on the diagram:

Attach the stripped wires loosely over the end of the channel

so they don't slow the projectile as it passes the rudimentary switch. Pull back the rubber band or the spring and watch the projectile

hit the target. You might have to adjust the distance between the target and

the end of the channel. You might have to experiment with the number of windings in order

to make a strong enough magnet to hold the target. I hope you will persevere with the experiment and you will feel the

joy of success and get an understanding of what experimental physicists

and what engineers do. This practical hands-on type of teaching by Professor Miller and

by the teachers at Richmond Tech engaged me and taught me not only

physics but financial maths as well - perhaps the most important and

beneficial maths lesson of all. It was during form 3 when the maths

teacher taught us how to work out problems dealing with money. Hire purchase was a very common method of buying and paying for

goods during the booming 60s. With hire purchase, the purchaser makes

a small initial payment, a deposit, and agrees to pay the rest of

the purchase price over a period of time with regular payments. The

deposit plus the regular payments always added up to more than the

sticker price of the item. We completed many such calculations for

various goods that people bought on hire purchase. And we were able

to express the extra cost as a percentage of the original price. The

extra cost was outrageous, both as an amount and as a percentage.

The maths teacher encouraged us to pay for goods in full, to avoid

the added cost. Then the maths teacher introduced his class to a new financial term.

He introduced the term "depreciation", which means reduction

in value. And he showed us how to calculate the reduction of value

due to the depreciation of an item. New manufactured items depreciate with time, usually by about 15-20

per cent per year. I saw the depreciation as a gain for me, not as

a loss. I could now buy a used car at a much-reduced price. For example,

a five-year-old car depreciating at 15 per cent each year would cost

less than half of its original price. Purchasing my cars after they

had depreciated by more than 50 per cent has saved me a substantial

amount of money over many years of car ownership. Four-five years

is the "half-life" of a car, in terms of money. That is

a $60,000 car devalues to $30,000 in one half-life; it goes down to

$15,000 in another half-life. So you can buy a $60,000 car for $15,000

when it is eight-ten years old - what a bargain. An Aussie In A Parallel Universe

|